Faster industry R&D with Setfos workflows

Industrial teams building OLED and QLED displays, organic and perovskite solar cells, and photodetectors tend to move fastest when measurement and physics-based simulation work together. That cuts guesswork, shortens prototype loops, and makes results easier to transfer across projects and sites.

In this newsletter, we share three recent research examples that show how Setfos plus Fluxim instrumentation can extract real device parameters, explain performance limits, and guide the next design step. You will also find where to meet the Fluxim team in March, including a first public viewing of our prototype battery testing tool, the recording of our webinar on thermal stress and degradation, and the SimOEP 2026 save-the-date. First, here is where you can meet us in March.

Meet Fluxim in March 2026

Special Colloquium on Solid State Electrochemistry in Stuttgart

"It’s all about defects" brings leading researchers together to discuss defects across solid-state materials, batteries, ionic conductors, and electrochemical devices. March 6-7, 2026 at the Max Planck Institute for Solid State Research in Stuttgart.

The programme features keynote contributions and invited lectures from institutions including MIT, University of Oxford, Stanford University, EPFL, RWTH Aachen, University of Cambridge, UCSB, and many more.

We are also pleased that Fluxim’s Dr. Davide Moia will be part of the programme, contributing to the discussion on advanced characterization and understanding of electrochemical materials.

Davide will be presenting:

Towards a defect chemical perspective on halide perovskite solar cells

Sat 7th March 11.55 am

ModVal 2026 in Lausanne

ModVal focuses on modeling and experimental validation of electrochemical energy technologies. Fluxim will attend and present our prototype battery testing tool. The event runs March 10-11, 2026 at The Olympic Museum in Lausanne.

Fluxim at MODVAL 2026

We're not presenting at this year's ModVal, but as a happy sponsor we'll be there in person and will host the first public viewing of a new instrument we've been working on.

We'll showcase a prototype battery testing tool designed for electrochemical characterization and model validation in R&D environments.

Accelerate battery characterization from setup to insight

”The Battery Testing Tool” (name still under consideration - add your suggestions in the comments below if you are feeling creative) is a new bench-top system for cycling, EIS/GEIS, and thermal control. It is built for parallel cell testing and accelerated analysis of up to 8 coin or pouch cells in the current prototype workflow.

Fast setup

Set up Cycling/EIS/Cyclovoltammetry/PITT/GITT sequences in minutes for standard test routines

Richer insight

Intermittent impedance spectroscopy and automated post-processing for common workflows

Higher throughput

Parallel testing of up to 8 cells with thermal control

If you are building test capacity or want faster validation loops between experiments and models, register your interest to get updates, early access details, and a chance to share your requirements.

ICDT 2026 in Chongqing

ICDT is SID China's flagship conference and exhibition for display technology. Fluxim will attend to connect with OLED and microdisplay R&D teams working on simulation plus characterization workflows. March 31 to April 3, 2026 in Chongqing.

Fluxim's attendance at ICDT

Our colleague Dr. Lu Zhang will be attending ICDT and will be joining our distributor GSI/HTTR, who will have a booth there.

Lu will be presenting

70.3 Computational Design and Optimization of Subpixel Concepts for Innovative OLED Displays

Friday, April 3 | 8:30-10:30 | Meeting Room 10

You can message Dr. Zhang directly on WeChat to arrange a meeting to discuss our software and measurement instruments.

She will also be available at the Booth of our Chinese Distributor GSI/HTTR.

SimOEP 26 save the date

Save the date for SimOEP 2026, the 10th International Conference on Simulation of Organic Electronics and Photovoltaics, taking place 9-11 September 2026 in Winterthur, Switzerland at ZHAW.

Join modeling experts and device physicists from industry and academia to share practical advances in simulating OLEDs and organic and perovskite solar cells, from charge and heat transport to exciton dynamics and light propagation across length scales from nanometers to centimeters.

And yes, it is also a good excuse to come to Switzerland. Winterthur, our home city, is close to Zurich and easy to reach, with a walkable old town and plenty of great spots for informal discussions after the sessions. If you want mountains and lakes, they are an easy day trip away.

To get the SimOEP vibe and see the high calibre of talks and speakers please check out proceedings from our last conference, SimOEP’24.

Research spotlight

Setfos delivers value fast on its own and even more when connected to measurement

The strongest industry workflows do not treat simulation as a separate step. Instead, teams use measurement to anchor parameters, Setfos to fit and explain, and then simulation to predict design changes before the next prototype.

Below are three concrete examples from our customers, each pairing Setfos with a second tool to create a measurement plus simulation workflow.

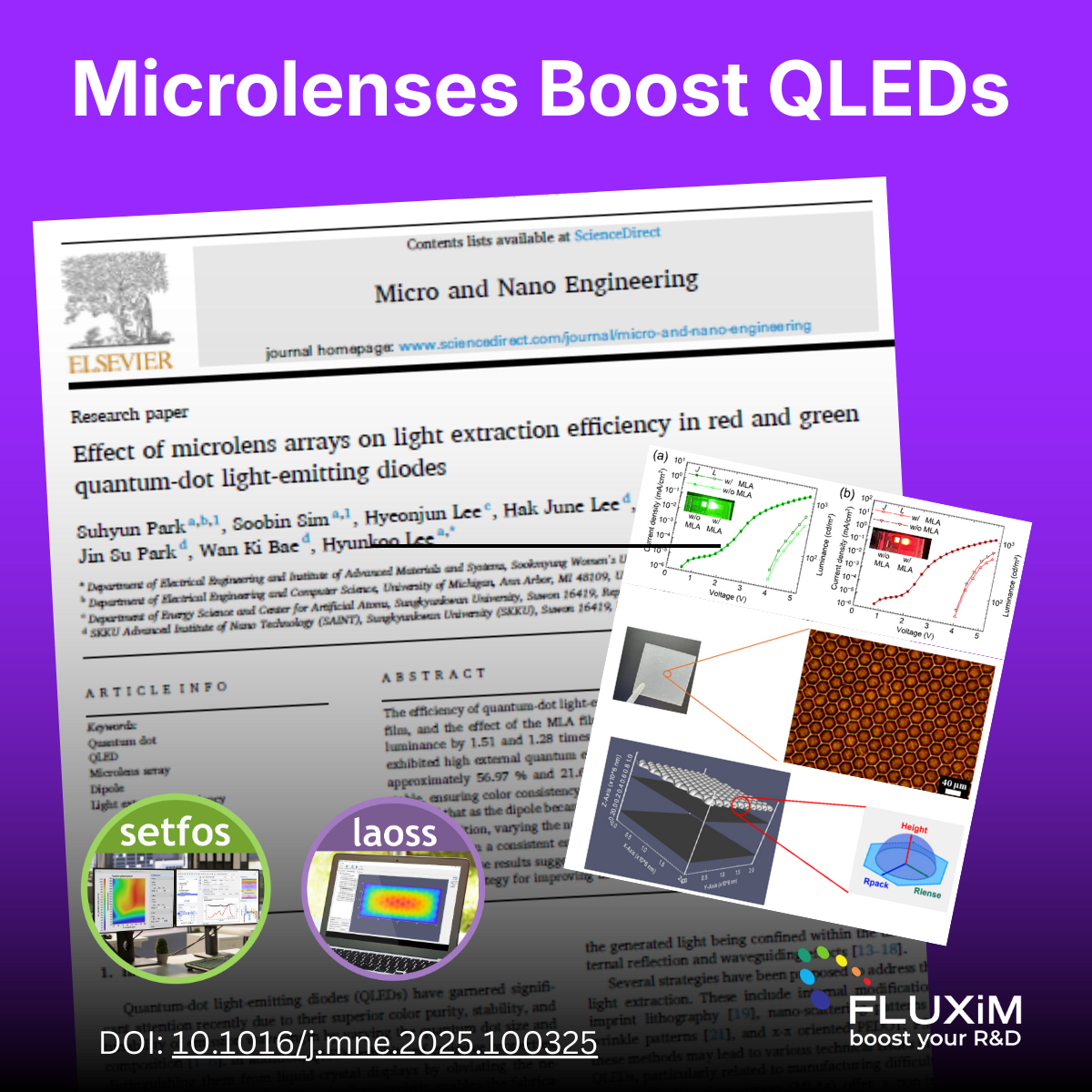

QLED outcoupling unlocked with Setfos and Laoss

A recent study on red and green QLEDs shows that microlens array films can boost brightness and EQE by improving light extraction, without changing the electrical device stack. Using Setfos for emissive thin-film optics and Laoss for 3D ray tracing of the microlens geometry, the authors reproduced the extraction gains and mapped practical levers like dipole orientation and microlens density.

Why industry teams care

If you are developing QD-OLED, QLED, or microdisplay optics, this is the workflow pattern: measure optical constants → simulate the multilayer stack in Setfos → scale to real structures in Laoss → reduce trial-and-error iterations.

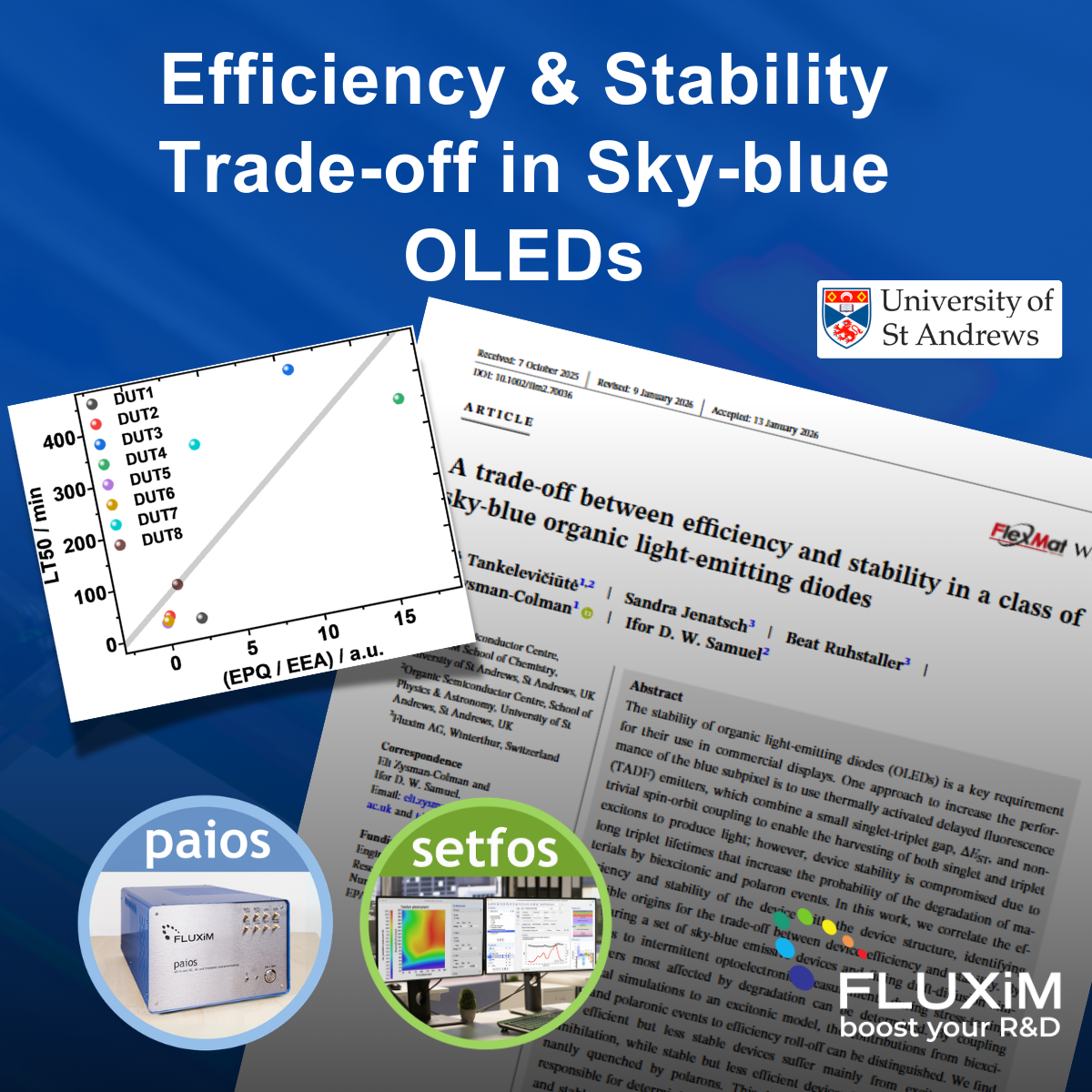

Sky-blue TADF OLEDs

Efficiency and stability trade-off in sky-blue OLEDs

Led by our sponsored Ph.D. student Egle Tankeleviciute (University of St Andrews), this study tackles a key industry challenge in sky-blue TADF OLEDs: higher efficiency often comes with shorter lifetime.

By combining Paios intermittent stress-test measurements with Setfos drift-diffusion fitting and a coupled excitonic model, the authors separate loss pathways and show a clear trend:

Less stable high-EQE stacks are mainly limited by exciton-exciton annihilation (EEA).

More stable stacks are dominated by exciton-polaron quenching (EPQ).

A higher EPQ-to-EEA rate ratio correlates with improved stability, and the biggest degradation-related parameter shifts are extracted in the emission layer (traps and reduced electron mobility in several stacks).

Industry takeaway

This is a repeatable workflow for R&D teams: measure degradation in real time, fit physics-based parameters, then redesign stacks based on the dominant non-radiative pathway - reducing guesswork and prototype cycles.

Fluxim tools used

Setfos drift-diffusion fits + coupled excitonic model to quantify EEA vs EPQ contributions

Emitter orientation and outcoupling tied together with Phelos and Setfos

Preferential horizontal emitter orientation is a proven route to higher OLED outcoupling. This recent study by Prof. Dr. Wolfgang Brütting’s group at the University of Augsburg, Germany shows host optical anisotropy as a practical lever for tuning emitter orientation across many cohost materials. The authors used Phelos to determine transition dipole moment orientation via angular-dependent photoluminescence, then used Setfos dipole-model outcoupling simulations to connect orientation and birefringence to EQE trends and optical loss channels.

Why industry teams care

This research connects material screening and optical stack design in one loop: measure orientation reliably, then simulate the real stack to quantify what actually reaches air and what is lost to guided and plasmonic channels.

Webinar 17 on thermal stress and degradation

If thermal effects and stability are part of your OLED or PV roadmap, Webinar 17 is a practical session to watch. The webinar features Dr. Fanny Baumann on multimodal tracking of perovskite solar cells operating at 85 C, followed by a live Setfos 6.0 demonstration focused on the thermal module and degradation models.

Industry focus

How industrial teams get more from Setfos

If your team develops OLED displays and other thin-film devices, Setfos becomes more valuable when you work from a consistent modelling baseline and reuse parameter sets across projects. This makes results easier to compare, reduces repeated fitting work, and helps teams make decisions based on shared assumptions.

Setfos 6.0 supports this with its material database, making it easier to build, reuse, and refine parameter sets across projects and sites. Teams use Setfos both to design OLED stacks in advance and to interpret performance after fabrication, including the impact of process variations.

What we typically support in industry

Proven simulation software refined over 20+ years

Direct support from researchers working on real device problems

Training from first fits to structured design studies and sensitivity analyses

Onboarding that shortens time to first useful results

Trusted by leading US and Asian consumer-electronics companies and major display manufacturers worldwide